Understanding Type 5 Building Construction: Definition, Benefits, and Applications

Building Type Cost Calculator

Calculate Construction Costs

Compare the cost of different building types based on UK market rates. Enter the building area to see the total construction cost for each type.

Cost Comparison

Cost Comparison with Other Types

Note: Costs based on UK market rates from the article. Actual costs may vary based on location, design complexity, and other factors.

Key Takeaways

- Type 5 building construction uses non‑combustible, load‑bearing walls made of concrete or masonry.

- It offers the highest fire resistance among the five standard building types.

- Commonly used for high‑rise apartments, hospitals, and industrial warehouses in the UK.

- Requires careful coordination with structural engineers because the walls support the entire load.

- Complies with UK Building Regulations Part A - fire safety and Part B - resistance to moisture.

When you hear “Type 5 Building Construction is a classification that relies on solid, non‑combustible walls to carry the building’s structural load,” you instantly know you’re dealing with the toughest of the five traditional building types. Unlike wood‑frame or steel‑frame approaches, every floor, roof and façade sits on thick masonry or concrete walls, which act like the building’s spine.

In the UK, builders and designers refer to this system when fire safety and durability are top priorities. Below we break down what Type5 really means, how it stacks up against the other four types, and when you should choose it for your next project.

What Exactly Is Type5 Building Construction?

Type5 building construction is defined as a system where load‑bearing walls are made of concrete, reinforced masonry, or similar non‑combustible materials. These walls support all vertical loads - floors, roofs, and even lateral forces like wind - without the need for an internal steel or timber frame.

Key attributes include:

- Walls typically 200mm or thicker, often reinforced with steel rebar.

- Fire rating of at least 2‑hour for walls and 3‑hour for floors, satisfying most UK fire codes.

- High thermal mass, which can improve energy efficiency when paired with proper insulation.

- Excellent resistance to moisture and pest intrusion.

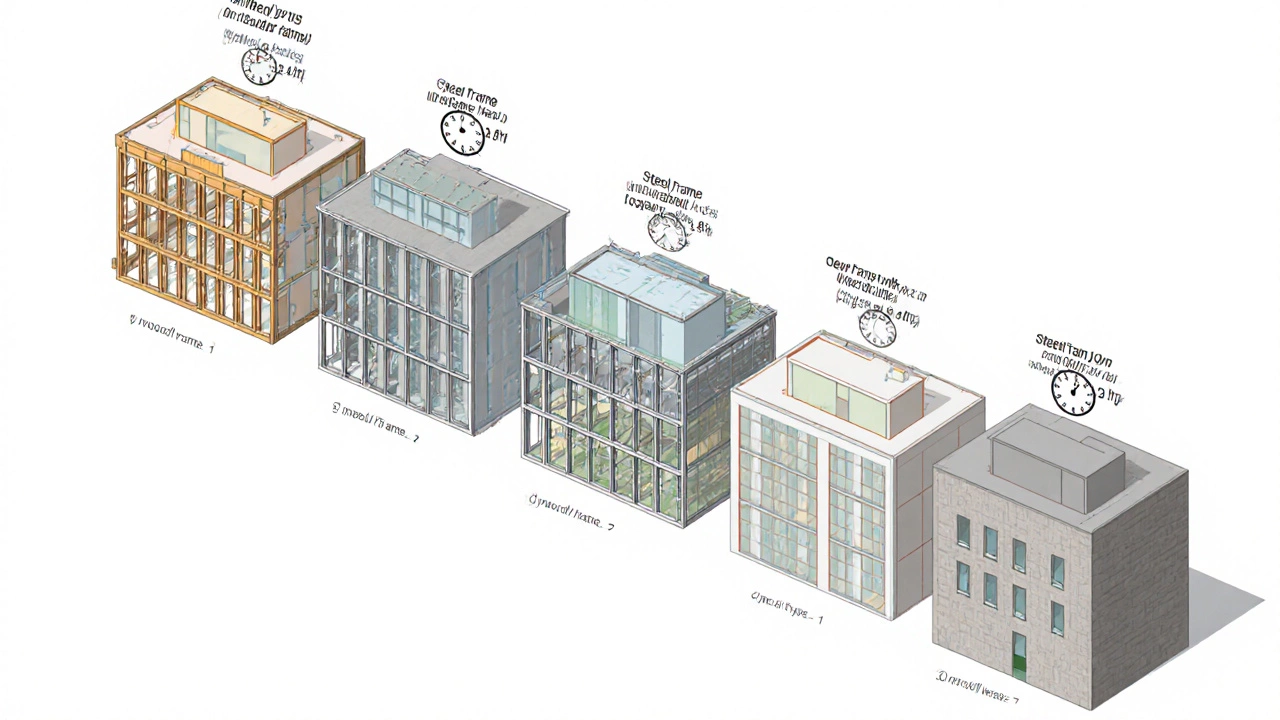

How Type5 Differs from Types1‑4

To appreciate Type5’s strengths, it helps to see it next to the other four classifications that the UK Building Control Service uses.

Type 1 Building Construction relies on wood‑frame walls, making it the most combustible option. It’s common for low‑rise residential houses.

Type 2 Building Construction uses non‑combustible materials for the exterior walls but still depends on a timber or steel frame for structural support. Think of many mid‑rise apartments.

Type 3 Building Construction features non‑combustible exterior walls with a steel or concrete frame; interior walls may be lightweight. It’s typical for office blocks.

Type 4 Building Construction uses a steel frame with non‑combustible exterior walls, often seen in warehouses.

Compared with these, Type5 eliminates the internal frame entirely - the walls themselves are the structure. This results in superior fire performance and fewer moving parts, but it also means heavier foundations and more rigorous engineering checks.

Typical Materials and Construction Techniques

The heart of Type5 is its load‑bearing walls, which can be built using several methods:

- Reinforced concrete: poured in situ or precast panels, offering high compressive strength.

- Reinforced masonry: concrete blocks or bricks with integrated steel reinforcement, a common choice for medium‑rise blocks.

- Insulated concrete formwork (ICF): combines concrete strength with built‑in insulation, improving energy performance.

Because the walls bear the load, the foundation must be sized accordingly. Typical foundations are reinforced concrete strip or raft slabs, designed to spread the wall loads over a larger soil footprint.

Benefits and Drawbacks

Every construction system has trade‑offs. Here’s a quick look at what makes Type5 attractive and where it might fall short.

| Feature | Type1 | Type2 | Type3 | Type4 | Type5 |

|---|---|---|---|---|---|

| Primary structural system | Timber frame | Timber/Steel frame + non‑combustible exterior | Steel or concrete frame | Steel frame | Non‑combustible load‑bearing walls |

| Fire rating (walls) | 30min | 1‑hour | 2‑hour | 2‑hour | 2‑hour+ (often 3‑hour) |

| Typical cost (per m²) | £1,200 | £1,400 | £1,700 | £1,800 | £2,200 |

| Common use | Detached houses | Low‑rise flats | Mid‑rise offices | Industrial warehouses | High‑rise apartments, hospitals, schools |

| Structural weight | Low | Medium | Medium‑high | Medium‑high | High |

**Pros**:

- Highest fire resistance; walls act as natural fire barriers.

- Durable - resistant to rot, termites, and moisture.

- Excellent acoustic isolation due to mass.

- Thermal mass can lower heating demand when paired with proper insulation.

**Cons**:

- Heavier structure demands stronger foundations, raising upfront costs.

- Longer construction time for wall pours and curing.

- Limited flexibility for future vertical extensions unless walls are designed for extra height.

Typical Applications in the UK

Because of its fire safety and robustness, Type5 is the go‑to choice for:

- High‑rise residential blocks in London’s regeneration projects.

- Hospitals and care homes where fire containment is critical.

- University lecture halls and laboratory buildings.

- Industrial facilities that require heavy‑duty floors and walls.

One notable example is the new student accommodation at Manchester’s Campus One development, which uses reinforced concrete load‑bearing walls to meet the required 3‑hour fire rating while delivering a sleek, minimalist façade.

Compliance with UK Building Regulations

Any Type5 project must align with several parts of the Building Regulations:

- Part A - Structure: Engineers must calculate wall load capacities, ensure adequate foundation sizing, and check for lateral stability against wind.

- Part B - Fire Safety: Minimum 2‑hour fire resistance for walls, 3‑hour for floors in high‑rise blocks. Sprinkler systems are often required for buildings over 18m tall.

- Part L - Conservation of Fuel and Power: High thermal mass can aid compliance, but insulation values (U‑values) must meet current targets - typically ≤0.18W/m²·K for walls.

- Part F - Ventilation: As walls are airtight, mechanical ventilation with heat recovery is common.

Working with a chartered structural engineer early on can help navigate these requirements and avoid costly redesigns.

Checklist: Is Type5 Right for Your Project?

- Do you need a fire‑rating of 2‑hour or higher? - Yes, consider Type5.

- Is the site capable of supporting heavier foundations? - Conduct soil bearing tests.

- Are you budgeting for higher initial costs in exchange for long‑term durability? - Perform life‑cycle cost analysis.

- Will the building require high acoustic performance (e.g., hospitals, schools)? - Type5 excels here.

- Is future vertical expansion likely? - Design walls with extra height capacity or choose a different system.

If most answers line up, Type5 could be the safest, most enduring choice.

Next Steps and Common Pitfalls

When moving from concept to construction, keep these tips in mind:

- Early coordination: Align architects, engineers, and the contractor on wall thickness and reinforcement layout.

- Accurate surveying: Any deviation in wall placement can affect load paths.

- Quality control on concrete: Use proper curing methods to achieve designed strength.

- Plan for services: Electrical, plumbing, and HVAC ducts must be routed through chases before walls are poured.

- Check fire-stopping details: Penetrations need fire‑rated sleeves to maintain wall integrity.

Skipping any of these steps often leads to costly rework or compliance issues.

Frequently Asked Questions

What makes Type5 more fire‑resistant than the other types?

Because the walls themselves are made of non‑combustible concrete or reinforced masonry, they act as a continuous fire barrier. The mass of the material also slows heat transfer, giving occupants more safe evacuation time.

Can I add a steel frame inside a Type5 building?

It’s possible, but it defeats the purpose of pure load‑bearing walls and adds complexity. If extra spans or large open spaces are needed, many designers switch to a hybrid system, keeping the walls for fire protection while using steel beams for longer spans.

Is Type5 suitable for low‑rise housing?

It can be, but the higher material and foundation costs usually make timber or Type2 more economical for small houses. Type5 shines in multi‑storey blocks where fire safety and durability outweigh the extra expense.

How does the construction timeline compare to other types?

Wall pours and curing add days to the schedule. A typical 5‑storey block may take 2‑3 weeks longer than a comparable Type3 steel‑frame building, largely due to concrete work and foundation reinforcement.

What insulation methods work best with Type5 walls?

External thermal insulation systems (ETICS) are popular, as they don’t compromise the structural wall. Interior rigid board insulation can also be used, but care must be taken to avoid thermal bridges at wall junctions.

Write a comment