Understanding Type C Construction in Commercial Buildings

Type C Construction Compliance Checker

Check if your project qualifies for Type C Construction

Type C construction allows a balance of cost and safety for mid-rise commercial buildings. This tool helps you verify compliance with IBC requirements.

Type C Construction Basics

• Structural members must be non-combustible (steel, concrete, masonry) • Interior combustible elements require fire-rated assemblies • Maximum height: 85 feet (about 7-8 stories) • Fire sprinklers required for buildings over 85 ft or with specific occupancy

Compliance Results

Enter your project details above to check compliance.

When you hear the term type C construction, you might picture steel frames, concrete slabs, and a lot of fire‑resistant walls. In plain English, it’s the building method that lets you put together sturdy, mid‑rise commercial projects without the cost and weight of a full fire‑proof system.

Type C construction is a classification under the International Building Code (IBC) that permits a mix of non‑combustible and combustible materials. The code allows load‑bearing walls made of concrete, masonry, or steel, while letting non‑structural elements like partitions be built from wood or other combustibles, as long as they meet fire‑resistance requirements.

Key Takeaways

- Type C construction balances cost and safety, making it ideal for many commercial projects.

- It uses non‑combustible structural members (steel, concrete, masonry) with limited combustible interior finishes.

- The International Building Code sets clear limits on building height and area for Type C structures.

- Proper fire‑resistance ratings on walls and floors are essential to stay within code.

- A quick checklist can help you confirm compliance before you break ground.

What Exactly Is Type C Construction?

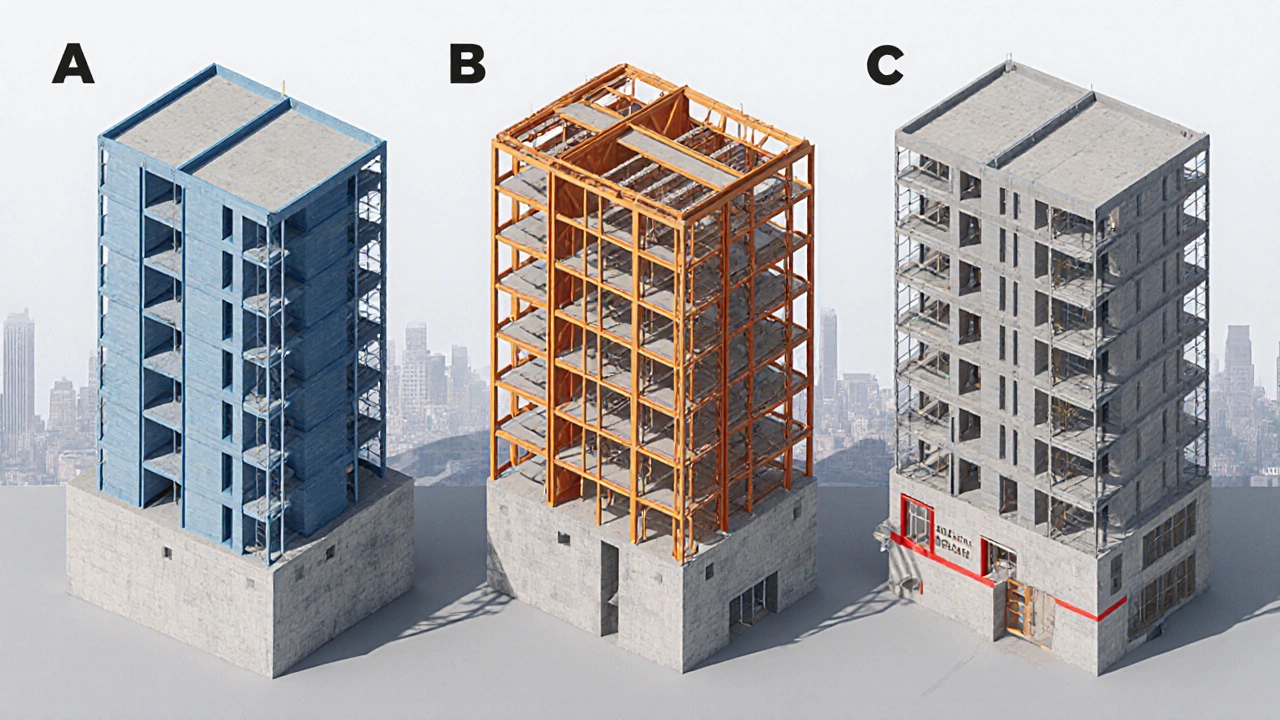

In the U.S., the IBC splits building types into three main groups: A, B, and C. Type A is the most fire‑resistant, requiring all structural elements to be non‑combustible (steel, concrete, or masonry). Type B relaxes the rule a bit, allowing exterior walls to be combustible if they meet certain fire‑rating thresholds. Type C, the middle ground, insists that the building’s load‑bearing system be non‑combustible, but it permits interior non‑structural components to be combustible, provided they’re protected by fire‑resistant assemblies.

Think of a typical office block in Manchester: the skeleton is steel, the floors are concrete, but the interior office partitions might be gypsum board over wooden studs. That’s a classic Type C scenario.

How Does Type C Differ From Types A and B?

Below is a quick side‑by‑side comparison:

| Aspect | Type A | Type B | Type C |

|---|---|---|---|

| Structural Material | All non‑combustible (steel, concrete, masonry) | Non‑combustible or limited combustible with fire‑rating | Non‑combustible load‑bearing members only |

| Interior Finish | Non‑combustible or fire‑rated | Fire‑rated assemblies required | Combustible allowed if protected |

| Typical Height Limit (IBC 2024) | Unlimited, subject to other codes | Up to 85 ft (about 7-8 stories) | Up to 85 ft (about 7-8 stories) |

| Cost Implications | Highest - full fire‑proof system | Moderate - some combustible elements | Balanced - cheaper interior, robust structure |

When Is Type C Construction the Right Choice?

Here are a few scenarios where Type C shines:

- Mid‑rise office or retail buildings - up to 85ft tall, where you want steel framing but don’t need a full fire‑proof envelope.

- Renovations of existing structures - you can keep the historic façade while upgrading the interior with modern, cost‑effective finishes.

- Warehouse extensions - the load‑bearing system stays steel, but you can line the interior with lighter, combustible partitions for quick re‑configuration.

In Manchester’s city centre, many mixed‑use developments use Type C for the lower office floors and switch to Type A for the upper residential units, optimizing both budget and safety.

Code Requirements: What the International Building Code Says

The latest IBC (2024 edition) spells out three key rules for Type C construction:

- Structural members must be non‑combustible. This includes steel joists, concrete slabs, and masonry walls that carry loads.

- Any combustible interior elements must be separated from the structural frame by a fire‑resistant assembly, usually rated 1‑hour or higher.

- Buildings cannot exceed the prescribed height and floor‑area limits without additional fire‑suppression systems such as sprinklers.

For a practical example, a 6‑story office building using Type C can qualify for a reduced sprinkler requirement if the fire‑resistance rating of interior walls meets the 2‑hour standard.

Choosing Materials: Non‑Combustible Meets Cost‑Effective

Below are the most common materials you’ll encounter in a Type C project, each with a microdata definition at first mention.

Structural steel is the backbone of many Type C frames. Its high strength‑to‑weight ratio lets you span large distances without massive columns.

Concrete offers fire‑resistance and excellent compressive strength, often used for floor slabs and shear walls.

Masonry (brick or block) provides both load‑bearing capacity and natural fire‑resistance, making it a favorite for exterior walls.

When you pair these non‑combustible members with a non‑combustible material rating (e.g., 1‑hour gypsum board), you meet the IBC’s fire‑protection requirement without inflating costs.

Cost and Speed: Why Developers Like Type C

Compared to a full Type A build, Type C can shave 15‑20% off material costs because you avoid fire‑proofing every interior surface. Construction schedules also improve - installing lightweight steel frames and concrete slabs is faster than building massive masonry walls.

However, you do need extra coordination on fire‑rating assemblies. Skipping that step can lead to costly re‑work during inspections.

Quick Planning Checklist for Type C Projects

- Confirm the building height does not exceed the IBC limit for Type C (typically 85ft).

- Verify that all load‑bearing elements are steel, concrete, or masonry.

- Choose interior finishes with appropriate fire‑resistance ratings (e.g., 1‑hour gypsum board).

- Coordinate fire‑sprinkler system design - taller buildings may need full coverage.

- Run a code compliance check with the local authority (Manchester City Council Building Control).

- Plan for future adaptability - modular interior partitions work well with Type C structures.

Common Mistakes to Avoid

Even seasoned contractors slip up when working with Type C. Here are the top three pitfalls:

- Assuming any wood is okay. Only non‑structural, fire‑rated wood assemblies are allowed.

- Ignoring height limits. Going beyond 85ft without sprinklers or compartmentalization will force a switch to Type A.

- Missing fire‑stop detailing. Gaps around penetrations (pipes, ducts) must be sealed with fire‑stop material, otherwise the entire wall rating is compromised.

Frequently Asked Questions

What is the main benefit of Type C construction?

It offers a solid, non‑combustible structural system while allowing cheaper, lighter interior finishes, which balances safety and cost.

Can I use Type C for a 10‑story building?

Typically no. The IBC caps Type C at about 85ft (≈7-8 stories) unless you add a full sprinkler system and meet stricter fire‑rating criteria, effectively moving the project toward Type A.

Is Type C allowed for residential units?

Residential occupancies generally require higher fire protection. In most cases, Type A or a specially approved fire‑resistance plan is needed, especially for multi‑family buildings.

Do I need a fire‑engineering report for Type C?

If your project pushes any of the IBC limits (height, area, or unusual materials), a fire‑engineer’s analysis will be required to prove compliance.

How does Type C impact insurance premiums?

Insurers view Type C as lower risk than fully combustible construction, so premiums are usually lower than for Type B, but higher than for pure Type A structures.

Bottom Line

Type C construction gives you the strength of steel or concrete without the expense of a fully fire‑proof envelope. By understanding the IBC rules, picking the right non‑combustible materials, and following a solid checklist, you can deliver a safe, cost‑effective commercial building that fits within Manchester’s urban fabric.

Write a comment